John Proud, Master Horner

June 10, 2010 by Bill Carter

Filed under Master Horner Profiles

Please click here for the entire article as presented in The Horn Book.

Lee Larkin, Master Horner

June 10, 2010 by Bill Carter

Filed under Master Horner Profiles

Please click here for the entire article as presented in The Horn Book.

Roland Cadle, Master Horner

June 10, 2010 by Bill Carter

Filed under Master Horner Profiles

Please click here for the entire article as presented in The Horn Book.

Wild Willy Frankfort, Master Horner

May 11, 2010 by Bill Carter

Filed under Master Horner Profiles

Please click here for the entire article as presented in The Horn Book.

The Screw Tip Powder Horn (The Horn Book – Feb 2007 edition)

May 3, 2010 by Bill Carter

Filed under Articles from the Archives

The Horn Book is the official publication of the HCH; it is published three times per year. It features pertinent information about the HCH, its members, and all kinds of horn objects. The following is an article from the February 2007 edition by Roland Cadle & Art DeCamp.

An American Legacy: The Screw-Tip Powder Horn

The screw-tip powder horn is as uniquely American as the

famous Kentucky long rifle with its hinged, brass patch box.

By Roland Cadle & Art DeCamp

The American screw-tip powder horn was an innovation by professional horners, turners, and a few rifle makers. With production centered in Eastern Pennsylvania in its earliest years, the screw tip horn thread its way South on the great wagon road, west through the Cumberland Gap and across Forbes Road and down the Ohio River, thus paralleling both the production and migration of the rifle it served. Our most respected “rifleman” scholar craftsman, Wallace Gussler, often illustrates these points while wearing a hand-made, linen rifleman’s shirt and carrying an American rifle, pouch and Pennsylvania screw-tip horn, each item the earliest known American type. Turned ends and threaded, removable tips, dating to the 17th Century, can be found both in England and on the European continent. So, in what way is this ancient technology uniquely American? Simply put, it is the application of a screw on tip, or screw-tip, on an otherwise naturally shaped cow horn. In Europe, this was not done on powder horns because quantity was not needed and the natural shape of the horn was modified to show the application of the “mystery and art” of the horner’s craft. So, let’s look at the American Screw-Tip… During the French and Indian War, the Colonies were divided into Northern and Southern districts.The Southern district included Pennsylvania, Delaware, Maryland,Virginia, North Carolina, South Carolina, and Georgia. The screw-tip is a product of the Southern district. At least three horners, located half a block from the wharfs of Philadelphia in Strawberry Alley, advertised “the finest powder horns” for sale during the French and Indian War. As early as 1759, one horner named Christopher Anger advertised “The finest American Made powder horns, combs, spoons, etc. at the sign of The Golden Powder Horn and Comb.”We believe the screw-tip powder horn originates in one of these shops.

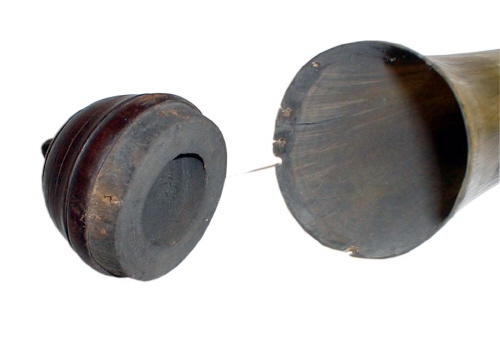

Screw-tip horns come in two distinct types.The tip either screws off (external) or screws in (internal). The earliest known screw-tips are internal with an applied collar to reinforce the threads, coming from Southeast Pennsylvania Dateable external types are currently traceable to the mid 1770’s. Before we give a school and region overview, let’s answer the obvious question: “Why a Screw-Tip?”

Various writers have dealt with the removable turned horn tip as strictly a utilitarian device – remove the tip and it facilitates refilling the horn by serving as a funnel (external screw tip) or leaving a bigger hole (internal screw tip) to allow quicker refill with a funnel. Since all horns are refilled by funneling the powder into the horn, it seems a prodigious amount of work just to cut twenty-six seconds off the refill time. Rather, we believe the size of the screw hole was more a happy byproduct of the production process in the quest for speed. Mechanically speaking, the screw tip allows for division of labor within a shop (an 18th Century factory concept), thus allowing several operations on the same horn nearly simultaneously. Turner One swages the hot horn onto a mandrel, turns the base of the horn true, and adds any integral molding (the double lines or surface bead of a York County horn).Turner Two takes the diameter of the horn base and turns a plug to fit. Using a tap inserted into the tip of the horn,Turner Three either tapers the end for an applied collar (internal screw tip) or shoulders or chases a set of threads (external screw tip).Turner Four can turn the respective screw tip, and then all of the parts go to the finishing room where the horn is scraped, polished, dyed or decorated and assembled. As late as 1840 records show two shops in Lancaster, Pennsylvania producing almost 20,000 horns a year using this basic method.

External Screwtip

Internal Screwtip

Concave Berks Plug

These are some general observations about the screw-tip powder horn, but a picture is worth a thousand words. This article presents information and photos of six distinct screw-tip horn varieties that seem to turn up most frequently within Pennsylvania.These are the most commonly seen varieties even though, through collecting and observing original powder horns, there may be as many as twelve different “schools” within Pennsylvania, made in at least eighteen different shops. Each of the six known “schools” is presented hereafter in approximate chronological sequence.

Early Philadelphia Horns (Circa 1750’s to 1780’s)

Early Philadelphia horns have a high domed hardwood base plug (usually maple) with a wide over hanging edge next to the horn and a concave “wasp’s waist” just above the bead. Like most other screw-tip varieties, the base plug is hollowed out on the lathe to help prevent checking. Frequently, there is a turned horn, or metal band at the base end of the horn.Wire staples are used for attaching the carrying strap at the spout and base end.The staple in the base can be staked like a staple with two legs, or is often bent into a loop, twisted, and inserted through a hole in the center of the plug, and clinched over on the inside.There is always a heavy applied collar on the mouth of the horn, used to reinforce the internal threads, that often appears larger in diameter at the spout end than at the back end.The screw-tip itself is of the internal type and is generally turned in the shape of a chess pawn.

PHILADELPHIA HORN

Berks County Horns (Circa 1790 to 1820)

There are at least four different shops that made the “Berks” style horn which is characterized by the oblong wooden base plug with an integrally turned button for attaching the carry strap.The screw-tip is of the internal variety, with an applied collar at the spout to reinforce the internal threads. The base plug is always turned with an undercut at the overhang where it joins the horn such that the edge of the horn is actually captured by the wooden plug.

BERKS COUNTY HORN

Lancaster Horns (Circa 1770 to 1890)

Lancaster horns are possibly the most common variety having been made in Lancaster for at least 120 years, by at least four different shops. This is the first of the external screw-tip styles. Many Lancaster horns have the low dome, flat base plug with impressed “rope” on the top of the plug. Staples are used at both ends for strap attachment. The elongated, gracefully turned screw-tip features external threads. Even though this style was made for such a long period, the basic form of the design did not vary greatly over the course of time.

LANCASTER COUNTY HORN

York Horns (Circa 1775 to 1830)

York horns are similar to the Lancaster type in that they have external screw tips. York horns, however, are much more highly developed from a design, fit and finish, and aesthetic perspective.York horns utilize fruitwood such as apple, pear, and cherry for their plugs, which are turned concave inside.The “classic”York horns have the high dome base plug with chip and rope carving.The external screwtips are turned in a finer manner with more decorative flair, usually featuring a number of grooves and raised beads. A pair of concentric grooves, forming a bead, are cut at both the base and spout ends of the body of the horn.

YORK COUNTY HORN

Franklin Horns (Circa 1790 to 1820)

Franklin County horns are external screw-tip horns with great similarity to York horns. Key differences are their almost flat, low domed base plugs and a set of three concentric grooves forming a double bead, turned in the base of the horn. The screw-tips are generally shorter than York horns, and feature a wide base end and very thin spout.

FRANKLIN COUNTY HORN

Centre Horns (Circa 1798 to 1845)

Family members originally trained in York, PA made Centre County horns. Thus they are of similar construction, but much more simple in actual execution. They feature a domed wooden base plug with an iron staple for the strap attachment and a squared staple at the neck for a front strap attachment. There is a single decorative bead turned on the base plug next to where it contacts the horn. The external screw-tip is simple, with a beehive type turning at its base. In conclusion, the distinct threaded, turned tip and turned base plug became the signature of the Pennsylvania screwtip horn and reflected the shop or region from which it came. These professional, shop-made powder horns are truly unique American relics. New examples of these horns continue to surface and undoubtedly will adjust our understanding of where and who made them.

CENTRE COUNTY HORN